1、激光熔覆智能再制造技术及设备(Laser cladding intelligent remanufacturing technology and equipment)

通过在激光熔覆系统中引入智能感知系统,可以完成基于熔池温度、形状的感知,进而监控熔池的实时状态,从而确保激光熔覆再制造过程中控形、控性、控轨迹,大大降低了激光熔覆过程中产生的残余应力以及裂纹,实现了激光熔覆过程中的智能化。

By using intelligent sensing system, the real-time state of molten pool can be monitored based on the temperature and shape perception of molten pool. Besides, the shape、the property and the trajectory are all control, reducing the residual stresses and cracks generated in the process of laser cladding, Finally, the intellectualization of the laser cladding process can be fulfilled.

图1 激光熔覆智能再制造技术及设备

Figure 1 Laser cladding intelligent remanufacturing technology and equipment

2、激光清洗技术及装备(Laser cleaning technology and equipment)

激光清洗是一种“干式”清洗技术,不需要清洁液或其它化学溶液;同时,清除污染物的种类和适用范围较广泛。通过调控激光工艺参数,可以在不损伤基材表面的基础上有效去除污染物可以方便实现自动化操作。视频1为采用该技术清洗云母带的操作,图2为清洗完后的云母带,清洗后,其表面的胶布完好无损。

Laser cleaning is a ‘dry-type’ technology without cleaning or other chemical solutions. Additionally, this technique is widely applied and many types of pollutants could be cleared away. By adjusting the laser process parameters, the pollutants can be effectively removed without damaging the surface of the matrix, fulfilling automatic operation. Video 1 shows the operation of mica tape cleaning, and in Figure 2, it can be seen that the adhesive tape on the matrix surface is intact after laser cleaning.

视频1 激光清洗云母带

Video 1 Mica tape laser cleaning

图2 激光清洗后的装备表面

Figure 2 Surface of equipment after laser cleaning

3、立柱表面处理(Surface treatment of vertical column)

对立柱表面进行处理,其基体表面硬度可以达到HRC30~58,使用寿命是国内立柱的5~6倍,具有技术先进、安全性能高、生产能力强等突出特点。同时,可以减少立柱更换检修时间、提高生产效率,同时又能节约大量的资金,对于建设节约型社会有着广泛而深远的意义。

After the modification of the vertical column, the hardness of the matrix surface could be 30-58HRC and the service life is prolong to 5-6 times than the untreated equipment. Meanwhile, it has good performance in the field of advanced technology, high safety performance and production capacity. Futhermore, the replacement and repair time of the vertical column is reduced, the production efficiency is improved and a lot of money is saved, which has a significance impact on building a conservation-oriented society.

图3 立柱表面处理及再制造

Figure 3 Surface treatment and remanufacturing of vertical column

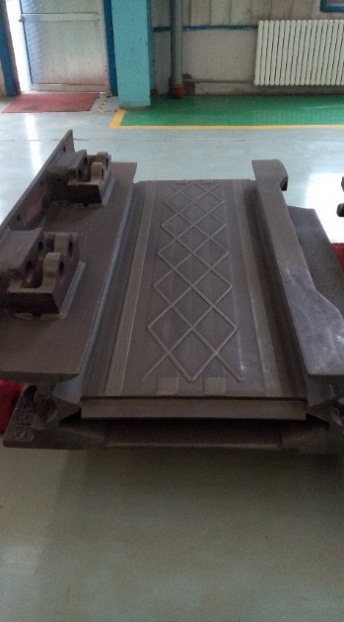

4、刮板机中部槽处理(The central trough processing of the scraper machine)

中部槽是综采工作面刮板输送机的易损件,由于货载(煤和矸石)、刮板和链在中部槽中滑行,故工作阻力大,磨损十分严重。由于链条、刮板及煤流的作用,中部槽磨损很快,主要表现在中板及槽帮的磨损,以及采煤机沿中部槽移动所造成的槽帮上部的磨损。

The middle slot is the vulnerable part of the scraper conveyor in the fully mechanized mining face. Because the load (coal and gangue), the scraper and chain slide in the middle slot, the working resistance is high and the wear is very serious. Because of the action of the chain, scraper and coal flow, the wear of the middle groove is very fast, which is mainly shown in the wear of the middle plate and groove side, and the upper part of the groove side caused by the coal mining machine moving along the middle groove.

在中板上支撑链条部分按照需求增加2mm厚的菱形花纹状耐磨涂层,让链条在耐磨层上滑动,不与中板直接接触。在基体强度不降低的前提下,可进行多次表面处理,有效提高金属表面的耐磨性,延长中部槽的使用寿命。

The supporting chain part on the middle plate increases the diamond pattern wear-resistant coating about 2mm thick according to the demand, allowing the chain to slide on the wear-resistant layer and not directly contact with the middle plate. On the premise that the matrix strength does not decrease, the surface treatment can be carried out for many times to effectively improve the wear resistance of the metal surface and extend the service life of the middle groove.

图4 中部槽表面处理及再制造

Figure 4 surface treatment and remanufacturing of the central trough

5、矿用截齿(Mining pick)

矿用截齿是煤炭工业和采掘工程中掘进机和采煤机等矿用机械设备用来破岩落煤用的刀具。截齿在工作过程中,除了要承受高的压应力、剪切应力和冲击负荷外,还存在随着工作时间增加温度升高,导致截齿软化的问题,加速截齿的磨损,因此截齿在矿用机械设备中属于易损件,是更换量最大的煤矿机械零件之一。矿用截齿性能的好坏,影响着采煤设备生产能力的发挥、功率的消耗和工作的平稳性等,对提高掘进机和采煤机等矿用机械装备的生产效率和降低成本有着重要意义。

Mining cutters are cutter used for breaking rock and falling coal in coal industry and mining engineering. In the process of operation, in addition to bearing high pressure stress, shear stress and impact load, the truncated tooth also has the problem of softening as the working time increases with the increase of temperature, which accelerates the wear of the truncated tooth. Therefore, the truncated tooth is a vulnerable part in mining machinery equipment, which is one of the most replaced coal mining machinery parts. The performance of mining cutters affects the production capacity, power consumption and stability of mining equipment, which is of great significance to improve the production efficiency and reduce cost of mining machinery equipment such as tunneling machines and coal mining machines.

对截齿进行表面处理获得耐磨层,能够将截齿刀头与煤岩之间的磨损,转换为耐磨层与被截割煤岩之间的磨损,保护了截齿头,使截齿的使用寿命得到了很大的提高。从广义上讲,截齿耐磨层技术极大地促进了煤矿行业向节约型循环经济发展。

The wear-resistant layer is obtained by surface treatment of the truncated teeth, which can change the wear between the cutter head and the coal rock into the wear between the layer and the cut coal rock, which protects the cutter head and greatly improves the service life of the cutter. In a broad sense, the abrasion layer technology has greatly promoted the development of the coal mine industry to the economical circular economy.

图5 矿用截齿表面处理及再制造

Figure 5 surface treatment and remanufacturing of mine truncation tooth

6、盾构机(Shield machine)

盾构机拼装机齿圈为常见的失效部位,如图6所示,可以对主驱动密封钢环、拼装机大小齿圈、轴承位磨损处进行再制造(如图7),也可以对推进油缸缸体进行再制造。图8给出了盾构机刀盘再制造现场。

The assembly gear ring of shield machine is a common failure position, as shown in Figure 6. It can be remanufactured to the main drive seal ring, assembly gear ring of the size of the assembly, and bearing wear (as shown in Figure 7). It can also be remanufactured to the propulsion cylinder block. Figure 8 shows the remanufacturing site of shield machine cutter.

图6 硬岩盾构机 图7 盾构机拼装机齿圈失效

Figure 6 hard rock shield machine Figure 7 Assembly gear of shield machine fails

(a)再制造损伤检测 (b)再制造 (c)再制造加工(精磨)

(a) Remanufacturing damage detection (b) remanufacturing(c) Remanufacturing (fine grinding)

图8 盾构机拼装机齿圈再制造

Figure 8 Shield machine assembly gear remanufacturing

7、电厂吹灰管(Power plant blowpipe)

图9为针对吹灰器在山西某煤矿热电厂进行腐蚀污垢现场试验的效果图。为比较起见,图片(a)、(b)左边第一根管均为没有处理的吹灰器。可以看出,未处理的吹灰器由于污垢的粘附而导致吹灰器表面温度过高,在使用3个月后,已经过早出现了破坏。而其余三根处理过的吹灰器则均显示了良好的抗腐蚀污垢的性能。

Figure 9 shows the effect of field test on corrosion and dirt of a coal mine thermal power plant in Shanxi Province. For comparison purposes, the first tube on the left side of the picture (a) and (b) are unprocessed blowers. It can be seen that the surface temperature of the ash blower that has not been treated is too high due to the adhesion of dirt. After 3 months of use, the damage has occurred prematurely. The other three treated soot blower all showed good anti-corrosion properties

(a)使用前的加热套管 (b)使用3个月后的加热套管

图9 腐蚀污垢对加热套管的影响

(a) heating sleeve before use (b) heating sleeve 3 months after use

Figure 9 influence of corrosion dirt on heating sleeve

8、风机叶轮再制造(Remanufacturing of fan impeller)

工业上,大量通风机应用于焦化工厂、矿井、隧道等的通风和排尘等,风机的叶轮和机壳都有不同程度的磨损,直接影响到生产的顺利进行,因此通风机的再制造具有广阔的市场。

In the industry, a large number of ventilators are applied to ventilation and dust removal in coking plants, mines and tunnels, etc. The impeller and housing of the ventilators have different degrees of wear, which directly affects the smooth operation of production. Therefore, the remanufacturing of ventilators has a broad market.

采用新型再制造技术,在开展叶轮的失效分析、寿命预测、全寿命评估的基础上进行了金属3D打印技术再制造工程设计,使叶轮恢复并超过原技术性能和价值,解决了叶轮延寿、再制造的关键技术难题。

Based on the failure analysis, life prediction and life assessment of the impeller, the new remanufacturing technology is adopted to carry out the metal 3D printing technology remanufacturing engineering design, so that the impeller can recover and exceed the original technical performance and value, solving the key technical problems of the impeller's life extension and remanufacturing.

(a)焦化厂风机(a) coking plant fan (b)磨损报废的叶轮(b) Worn out impeller

(c)再制造中的叶轮

(c) Impeller in remanufacturing

(d)再制造后的叶轮

(d) Remanufactured impeller

图10 风机叶轮再制造

Figure 10 Remanufacturing of fan impeller